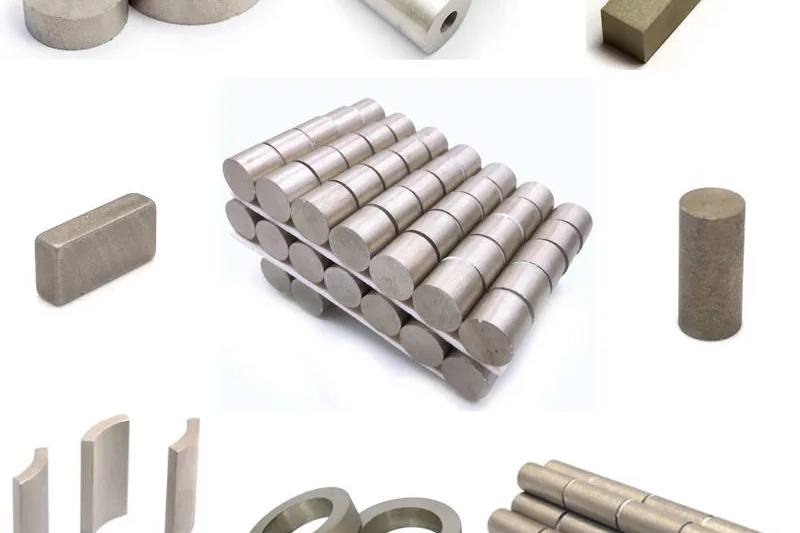

Your Best Custom SmCo Magnet China Manufacturer

- Material: XG24 ,XG26, XG28 ,XG30,XG32,XG33 etc

- Size: Customized

- Coating Ni, Nicuni, Black epoxy

- Apperance: Silvery ,Black

- Application: Industrial Motor, Servo Motor, Acoustic Component, etc.

- Working Temperature: <350℃

- Key words: SmCo magnet ,BLock ,Rod and Disc , Ring and Tube ,Arc Magnet ,Segment Magnet,Motor Magnet

SmCo Magnet Type Series

1. Stricture and Composition

SmCo magnets, taking the 2:17 type as an example, contain 23%-28% samarium, 48%-52% cobalt, 14%-17% iron, and small amounts of copper, zirconium, and other elements. the rare earth element neodymium (29- 32.5%), and boric acid (1.1-1.2%).

2. Magnetic Strength

SmCo magnets come in energy products from 16MGOe up to 33MGOe . Their high resistance to demagnetizing influences and excellent thermal stability has ensured SmCo AS the premium choice for the most demanding motor applications . in addition ,the corrosion resistance is significantly higher .

3. Grade and Size

it has a combination of very high remanence and coercivity and comes with a wide range of grades ,sizes and shapes .

4. Temperature Resistance

There are also differences in temperature resistance between NdFeB and SmCo magnets. Regular NdFeB magnets can generally reach 220°C, while Sm2Co17 can reach up to 350°C. At temperatures around 300°C, NdFeB has essentially no magnetic force, while SmCo can work normally without magnetic demagnetization.

5. Cost

NdFeB contains a smaller proportion of rare earth elements (neodymium and boron), making it relatively cheaper. SmCo contains many rare earth elements (about 70% samarium and cobalt), making it more expensive.

Why choose pufeite as SmCo magnet manufacture?

We want to bring our knowledge and experience to the forefront by actively participating in your upcoming projects. Work with our magnet experts to get the right magnet solution.

Our advantages

- We are manufacturer

- More than 10 years in this industry

- ISO/TS 16949 ,ISO 9001 ,Rohs

- Professional technical support

- Strict QC & Top quality

Application of Samarium Cobalt Magnets

Samarium Cobalt magnets are most commonly used in applications that require high temperature operation, such as generators, pump couplings, sensors, electric motors, marine applications as well as the automotive, aerospace, military, food and manufacturing industries.

Smco Magnets Advantages

We can provide you with a one-stop custom solution for high-strength magnets.

SmCo magnets (Samarium Cobalt) are known for their excellent temperature stability, with a maximum operating temperature range of 250°C to 350°C. They also have a lower temperature coefficient than neodymium magnets, typically between -0.03% and -0.05% per degree Celsius. While their magnetic strength is slightly lower than that of neodymium magnets, they are an excellent choice for high temperature applications.

Does samarium-cobalt magnets rust?

Cobalt-samarium magnets can rust because they contain iron components. So they will rust. However, compared to neodymium-iron-boron, the iron content is relatively low, so the rusting phenomenon will not be very serious. But if used in seawater, rust spots will appear on the surface, but it will not affect the performance and usage.

Performance table of sintered Samarium cobalt magnets

| Grade | Remanece ( 20°C) | Coercivity (20°C) | Intrinsic coercive force ( 20°C ) | Energy Density | Temp.coefficient %/C | Max.oper. Temp | Density | |||||||||||||

| Br | Hcb | Hcj | (BH) max | 20-100°C | 20-150°C | |||||||||||||||

| Typ. | min | Min | Min | Typ. | min | Tk (Br) typ. | Tk (Hcj) typ. | Tk (Br) typ. | Tk (Hcj) typ | |||||||||||

| KGs | Tesla | KGs | Tesla | KOe | KA/m | KOe | KA/m | MGOe | KJ/m3 | MGOe | KJ/m3 | %/°C | %/°C | %/°C | %/°C | °C | °F | g/cm3 | ||

| SmCo5 | XG16 | 8.50 | 0.85 | 8.00 | 0.80 | 7.50 | 597 | 18.00 | 1433 | 16.00 | 127 | 14.00 | 111 | -0.04 | -0.14 | -0.045 | -0.22 | 250 | 482 | 8.1-8.3 |

| XG18 | 9.00 | 0.90 | 8.50 | 0.85 | 8.00 | 664 | 18.00 | 1433 | 18.00 | 143 | 16.00 | 127 | -0.04 | -0.14 | -0.045 | -0.22 | 250 | 482 | 8.1-8.3 | |

| XG20 | 9.50 | 0.95 | 8.80 | 0.88 | 8.50 | 677 | 15.00 | 1195 | 20.00 | 159 | 18.00 | 143 | -0.04 | -0.14 | -0.045 | -0.22 | 250 | 482 | 8.1-8.3 | |

| Sm2Co17 | XG24A | 10.30 | 1.03 | 9.50 | 0.95 | 8.50 | 677 | 25.00 | 1990 | 24.00 | 191 | 22.00 | 175 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 |

| XG26A | 10.50 | 1.05 | 10.30 | 1.03 | 9.00 | 716 | 25.00 | 1990 | 26.00 | 207 | 24.00 | 191 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG28A | 10.70 | 1.07 | 10.50 | 1.05 | 9.50 | 756 | 20.00 | 1592 | 28.00 | 223 | 26.00 | 207 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG30A | 11.00 | 1.10 | 10.70 | 1.07 | 10.00 | 796 | 20.00 | 1592 | 29.00 | 231 | 27.00 | 215 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG30EH | 11.20 | 1.12 | 10.80 | 1.08 | 10.20 | 812 | 20.00 | 1592 | 29.50 | 235 | 28.00 | 223 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG32A | 11.50 | 1.15 | 10.90 | 1.09 | 10.30 | 820 | 20.00 | 1592 | 30.50 | 243 | 28.50 | 226 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG33EH | 11.70 | 1.17 | 11.00 | 1.10 | 10.50 | 836 | 20.00 | 1592 | 31.50 | 251 | 29.00 | 235 | -0.03 | -0.18 | -0.035 | -0.19 | 350 | 662 | 8.3-8.5 | |

| XG18AH | 10.00 | 1.00 | 8.50 | 0.85 | 8.00 | 637 | 30.00 | 2388 | 18.00 | 143 | 15.00 | 119 | -0.02 | -0.15 | -0.03 | -0.16 | 400 | 752 | 8.3-8.5 | |