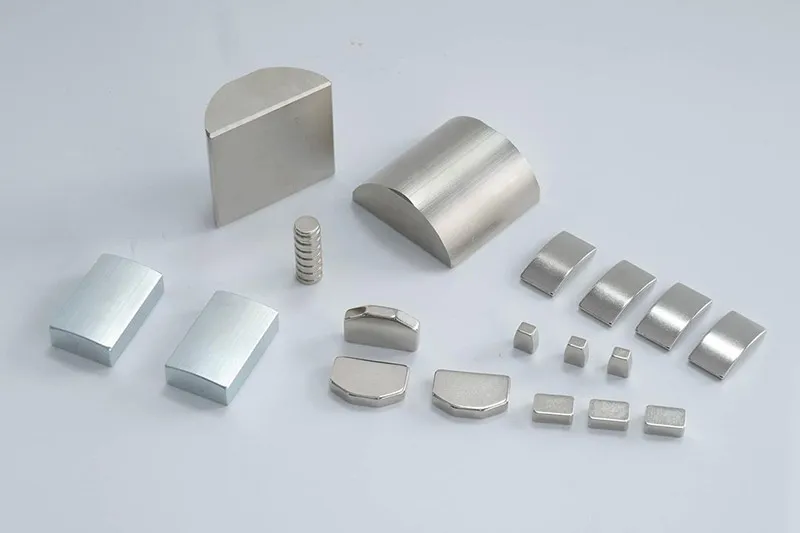

Your Best Custom Sintered Ndfeb Magnet China Manufacturer

- Material: N35, N42, N45, N52, 50M, 38H, 40H, 42H, 48H, 50H, 42UH etc

- Size: Customized

- Coating: Ni ,Nicuni ,Black epoxy

- Apperance: Silvery ,Black ,Yellow

- Application: Industrial Motor, Servo Motor, Acoustic Component, etc.

- Working Temperature: <150℃

- Key words: Neodymium magnet ,Arc Magnet ,Segment Magnet,Motor Magnet

Sintered Ndfeb Magnet Type Series

Neodymium iron boron magnetic material is the third-generation rare earth magnetic and permanent magnetic material based on the intermetallic compound Nd2Fe14B. Its main components are iron (63.9-68.7%), the rare earth element neodymium (29- 32.5%), and boric acid (1.1-1.2%). The main manufacturing processes include smelting, crushing, pressing and orientation, sintering, mechanical processing, coating and magnetization.

Sintered Ndfeb magnets are rare earth magnets which are the most powerful commercialized permanet magnets available today , with maximum energy product ranging from 26MGOe to 52 MGOe . it has a combination of very high remanence and coercivity and comes with a wide range of grades ,sizes and shapes .

Why Choose Pufeite as Ndfeb Magnet Manufacture

We want to bring our knowledge and experience to the forefront by actively participating in your upcoming projects. Work with our magnet experts to get the right magnet solution.

Applications of Sintered Neodymium Magents

NdFeb Magnets FAQs

Permanent magnetic material based on the intermetallic compound Nd2Fe14B. Its main components are iron (63.9-68.7%),they are prone to rusting when exposed to moisture and oxygen. To prevent corrosion, neodymium magnets are usually coated with coatings, such as nickel, zinc, epoxy, etc. However, if the protective coating is damaged or if they are exposed to harsh conditions, there is a risk of rusting.

The strength of a neodymium magnet is often measured in terms of its magnetic energy product. Neodymium magnets typically have a magnetic energy product ranging from about 33 to 52 mega-Gauss-oersteds (MGOe). For detailed information, please look at the table of “Grade of Neodymium Magnets” on this page.

Most magnet manufacturers use laser engraving to add logos and “NS” marks. The laser engraving effect is quite good. There is no problem with surface coating Zn or Ni , Some customers also choose the low-cost option of marking lines.

NdFeb Magnets Advantages

- Very high resistance to demagentization

- Highly refined processing, precise dimensions

- Good in ambient temperature

- Moderately priced

- material is corrosive and should be coated for long term maximum energy output

- Low working temperature for heat applications ,but higher levels of heat resistance materials are being introduced periodically.

Our Advantages

- We are manufacturer

- More than 10 years in this industry

- ISO/TS 16949 ,ISO 9001 ,Rohs

- Professional technical support

- Strict QC & Top quality