Multi-pole Radial Oriented Sintered Ndfeb Ring magnets China Manufacturer

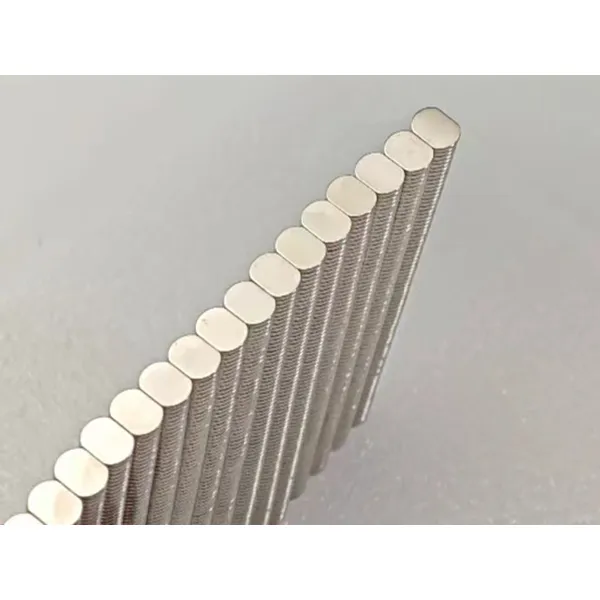

- Material: Neodymium (Nd) magnet

- Size: Customized

- Magnetization: Skewed Magnetization,Radially Oriented Magnetization

- Key words: Multipole Radial Ring neodymium magnets,radially oriented ring magnet

- Max working Temp: 80℃-180℃

- The regular coating is NiCuNi and Epoxy.

- Application: Robotics and Industrial Automatic ,linear actuator application

Multi-pole Radial Sintered Ndfeb Ring magnets Series for high-end Motor

- Most permanent magnet motors, they use a magnetic Arc, and put them together into a ring, which is an insert type the magnet inside the motor, are inserted one by one, which are matched with the winding inside, outside is the N pole, inside maybe the S pole, the winding in there just power on, which can attract or push it, through the continuous magnetic field changes of the coil, to drive the whole rotor to move.

- For radial Ndfeb ring magnets ,it is a radial 10-pole magnets, its magnetic pole distribution, it’s the whole place, is divided into 10 areas, here is a polar N/S ,N/S it is 10 poles alternating like this.

- The cost is relatively expensive this magnets production process is also relatively complex, it requires some precision molds directly in the forming process ,to make it into such a magnetic ring, in the process of forming, it needs to be oriented, this meas that its magnetic poles have been fixed ,and then we give it a special magnetization ,and this magnetization also requires special fixtures to give it this effect .

- The advantage of using this magnetic ring ,is that it is formed in one go, it reduces splicing in the middle, it reduces splicing in the middle and machining errors and other factors ,so such a magnetic ring the waveform of its entire magnetic field distribution ,after the waveform is good .

Why choose pufeite as Radial Oriented Sintered Ndfeb Ring magnets?

We want to bring our knowledge and experience to the forefront by actively participating in your upcoming projects. Work with our magnet experts to get the right magnet solution.

Radial Oriented Ring Magnet Applications

The classic design of magnetic rotors. Traditionally, arc segment magnets are positioned on a ring, with each segment magnetically aligned in the opposite direction (north or south) to the next magnet. However, with radial sintered rings, a single magnet can host opposite magnetic fields, such as 4, 8, or more circular multi-pole magnets. This capability is exclusive to this technology and cannot be achieved using any other method. the waveform is good ,it means that when it is installed in the motor ,the waveform of the entire motor will be very good ,so all high-end motors use it ,for the waveform of the entire motor ,have very high requirements ,will use it ,otherwise for ordinary ones to reduce costs ,most of them use Arc or square pieces to form the whole piece .

Radial Oriented Ring Magnet Advantages

Less part ,simplify assembly process ,easily realize automatic assembly .

Outer Diameter Highter precision ,Better Coaxiality and Verticality .

Very flexible to choose different ways of magnetizing ,include magnetizing poles and angles.

Highly reliable ,no risk of magnet peel off .

Very small air gap ,motor has smoother operating performance with less noise and vibration .