Neodymium Pot Magnet China Manufacturer

- Component Material: neodymium ring magnets + A3 steel cup + ABS plastic ring or epoxy glue

- Available Surface Treatment: Nickel, Zinc, spray colorful plastic

- Standard Size: diameter-16mm, 20mm, 25mm, 32mm,36mm,42mm,48mm,60mm,75mm

- Magnetic Grade: N35, N38, N40, N42, N45,N48,N50,N52

- Working Temp.: -40 to 80℃(for standard ones), the pot magnets for higher working temperature can be customized.

NdFeB Pot Magnets are best for small sized magnetic products with maximum pull strength (ideally when in direct contact with ferromagnetic e.g. mild steel surfaces). The actual pull force achieved is dependent on the surface that is being clamped onto (material type, thickness, flatness, friction levels, etc), its quality (e.g. rust free), its size (thickness plus total surface area), etc.

Products Categories

Get A Free Quote

What Are The Types of Pot Magnets ?

According to the fixation method ,there are six main types pf pot magnets

- Countersunk Pot Magnets: These have a countersunk hole on one face ,shich allows them to be easily mounted using a screw .

- Through Hole Pot Magnets: these have a hole through the center ,which allows them to be mountnted using a screw

- Internal Threaded Pot Magnets: these have an internal thread on one face ,which allows them to be easily screwed onto a threaded stud or bolt .

- Female Threaded Hole: These have a threaded stud on one face ,which allows them to easily screwed in to a threaded hole or nut .

- Hook Magents: these has a hook or eyelet attached to the top of the metal casing ,which allows it to be easily attached.

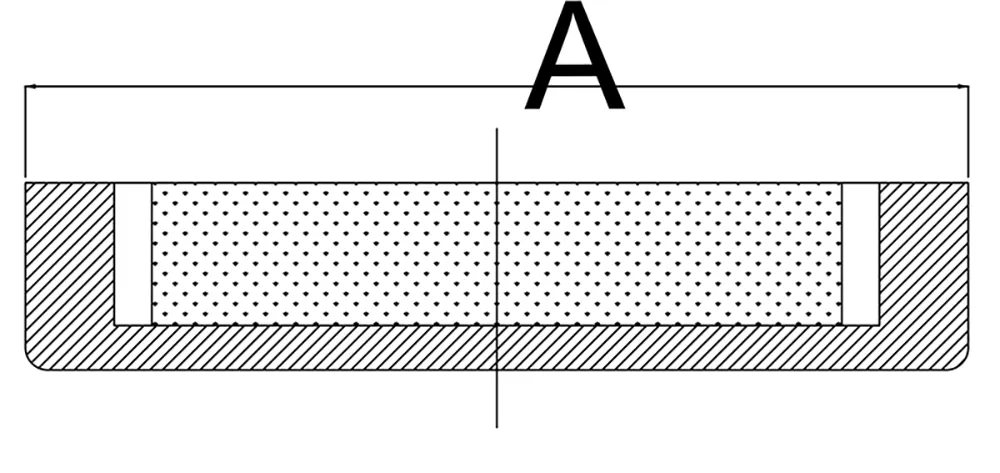

Pot Magnetic Holder

This type has a countersunk hole, can works in conjunction with countersunk head screw.

| Pot Magnetic Holder PFT05 Series | ||||

| No | Item code | Size (A*B) | Magnet type | Pull force |

| 1 | PFT05-06 | φ6×4.5 | Ndfeb | 0.35kg |

| 2 | PFT05-06A | φ6×3 | Ndfeb | 0.3kg |

| 3 | PFT05-08 | φ8×3 | Ndfeb | 0.4kg |

| 4 | PFT05-10 | φ10×3 | Ndfeb | 0.5kg |

| 5 | PFT05-13 | φ13×3 | Ndfeb | 1kg |

| 6 | PFT05-13.3 | φ13.3×10.4 | Ndfeb | 1kg |

| 7 | PFT05-17 | φ17×4 | Ndfeb | 18kg |

| 8 | PFT05-20 | φ20×6 | Ndfeb | 11kg |

| 9 | PFT05-20A | φ20×5 | Ndfeb | 10kg |

| 10 | PFT05-23 | φ23.3×4 | Ndfeb | 12kg |

| 11 | PFT05-25 | φ25×7 | Ndfeb | 20kg |

| 12 | PFT05-25A | φ25×7 | Ndfeb | 20kg |

| 13 | PFT05-25.4 | φ25.4×8 | Ndfeb | 22-24kg |

| 14 | PFT05-30 | φ30×8 | Ndfeb | 26kg |

| 15 | PFT05-32 | φ32×7 | Ndfeb | 35kg |

| 16 | PFT05-40 | φ40×8.5 | Ndfeb | 50kg |

| 17 | PFT05-40A | φ40×10 | Ndfeb | 60kg |

Why choose pufeite as Pot Magnets manufacture

We want to bring our knowledge and experience to the forefront by actively participating in your upcoming projects. Work with our magnet experts to get the right magnet solution.

- Competitive Prices

- Available in All Grades

- Tailored to Your Requirements

- Reliable Supply Chain for Fast Shipping

Pot Magnet Application

- They are commonly used in a variety of applications, including retail displays, trade shows, and exhibitions, workshops, garages, and other industrial setting.

- Choosing the ring pot magnet for your application involves considering several factors such as the required holding force ,size and shape of the magnet ,operating , temperatures and environmental conditions .Determine the required holding force this depends on the weight and type of the object you want to hold or attach

- make sure to choose a magnet with a sufficient holding force for your application . consider the size and shape of the magnet : choose a pot magnet that fits the available space and has a shape that is compatible with your application .

- consider the environmental conditions : pot magnets may be affected by environmental factors such as corrosion and exposure to chemicals . choose a magnet that can withstand the environmental conditions of your application .

- The maximum holding force of a pot magnet depends on various factors such as the size, shape, and material of the magnet, as well as the thickness and material of the surface it is attached to. It’s difficult to provide a specific answer without additional information.