1: Export Controls: China Officially Plays the Rare Earth Card

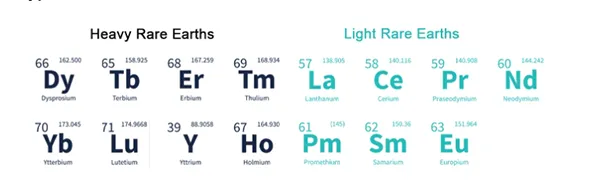

In April 2025, China announced the implementation of an export licensing system for seven rare earth-related products—samarium, gadolinium, terbium, dysprosium, lutetium, scandium, and yttrium. Most of these elements are classified as heavy rare earths, which are difficult to mine, require advanced separation technologies, and are critical for high-end magnetic materials, laser equipment, and aerospace alloys.

Image Source :dy6metals

You may not have heard of terbium or dysprosium, but these elements are essential to modern technology. From electric vehicle motors and wind turbines to military-grade lasers and the tiny vibration motors inside smartphones, their operation relies on rare earth elements.

Dysprosium is used in tandem with neodymium in magnets that are vital to modern tech and renewable energy. In addition, dysprosium oxide is used in nuclear reactors to help cool fuel rods to keep reactions under control.High-operating temperature magnets require Heavy REEs ‘Dy’ and ‘Tb’

Praseodymium’s largest market, together with Neodymium, is for use in Neodymium-Iron-Boron (NdFeB) magnets. Over 90% of all electric vehicles produced to-date use permanent magnet traction motors containing NdFeB,The magnets necessary in EV traction motors:

2: Solution: Neodymium Magnets without Controlled Rare Earth

The use of HREE-free NdFeB magnets is a method to enhance supply chain resilience.

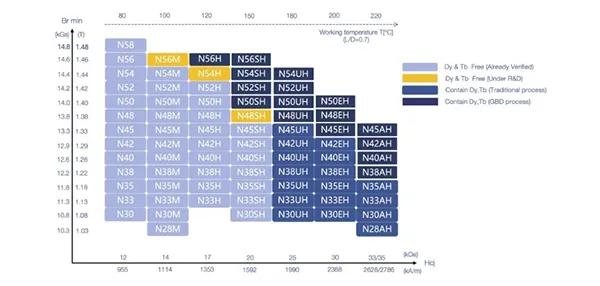

NdFeB magnet grades without dysprosium (Dy) and terbium (Tb) has become increasingly critical.

This chart provides a snapshot of our latest progress in Dy/Tb-free NdFeB development. It highlights a range of grades—some already confirmed free of these heavy REEs, others still in active R&D. These grades span a broad spectrum of magnetic properties, from remanence to coercivity, underscoring our commitment to delivering high-performance solutions without relying on supply-sensitive elements.

3: Benefit of HREE-free NdFeB magnets

Supply Chain: Reducing Dependence on Rare Earth Price Volatility. The price of heavy rare earth elements is influenced by various factors, including supply and demand, resulting in significant fluctuations. By using magnets, sensitivity to these factors can be decreased, resulting in more stable product costs.

Lower Raw Material Costs: The extraction and costs of heavy rare earth elements are high. Utilizing HREE-free NdFeB magnets that do not contain heavy rare earth elements can lead to lower raw material costs.

For the automotive, electronics, and industrial sectors, these innovations

1: Reduced supply chain risk

2: Greater cost stability by avoiding price-volatile heavy

3: Stronger alignment with sustainability and material efficiency goals

4: Pufeite Neodymium Magnet Manufacturer

Zhe Jiang Pufeite Magnetics Co;ltd is one of China Permanent Magnet Supplier ,Strong Motor Magnet Supplier ,Neodymium Magnet Manufacturer ,we have the advantages in below

1: Competitive Prices

2: Available in All Grades

3: Tailored to Your Requirements

4: Reliable Supply Chain for Fast Shipping

Photo from Pufeite Mexico exhibition

If you have any needs regarding Ndfeb magnets , please feel free to contact me.